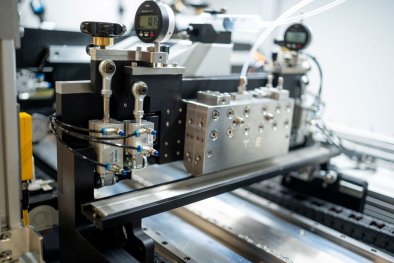

Computer aided automated device for controlled (in surface and thickness) and repeatable sequential mode of one-sided application of coatings on a flat surface (in size of up to DIN A4) with a selected module (rotary screen or Slot-die) and the possibility of drying with an advanced (quick and low energy) NIR radiation in a continuous sheet-to-sheet (S2S) process. The slot-die module enables the application on surfaces in a width of up 180 mm and in a thickness from several 10 nm to 100 µm (±2,5 µm) by using shim masks of various thicknesses and channel widths. The printing unit enables microscopic alignment of screen positioning (with a built-in camera and monitor), and thus high accuracy (±20 µm) and repeatability (±5 %) in case of successive multilayer coatings with a screen of various perforations and patterns. Dosing of the coating fluid/ink is automated/controlled with an operated injection pump (in case of a slot-die technique) or with pneumatically operated squeegees/knife (in case of a rotary screen). The software enables control of coating (i.e., determining the dosing rate, movement of the substrate, rotation of the screen, setting the thickness of the wet/dry coating, etc.) and drying (power and duration of NIR radiation) as well as operation control (real time monitoring).

The equipment is located at the Faculty of Mechanical Engineering, University of Maribor.

Equipment keeper: Prof. dr. Vanja Kokol.

Read more here.